Thermal Management Research Laboratory

TMRL was established during 2010 to conduct the research on improving the performance of optoelectronic devices like LED (for Solid State Lighting, SSL) and its research has been focused on advanced material and packaging technologies including thermal management by adopting an innovative and internationally recognized thermal management methodology (ASTM-compliant). TMRL is the first of its kind in Malaysia which specializes in thermal, optical and material analysis that supports leading semiconductor companies like Western Digital, Intel, Osram, LumiLEDs, Pentamaster, QDOS etc. We are currently working on simulation, testing and reliability studies to solve the thermal related issues in SSL and electronic packaging products by utilizing leading industrial softwares (FloTHERM, FloEFD, TracePro, TeraLED, COMSOL etc) and equipments (T3ster, TC- TPS2500 etc.).

1. Western Digital, Penang

2. Intel, Kulim

3. Osram, Penang

4. Pentamaster Sdn. Bhd., Penang

5. Regensburg University, Germany

6. Millennium Substrates Sdn Bhd, Penang

7. USAINS Infotech, Penang

8. QAV Technolgy Sdn. Bhd., Penang

9. QDOS Flexcircuits Sdn. Bhd., Penang

10. CREST, Penang

INDUSTRIES

1. Western Digital, Penang.

2. QAV Technologies Sdn.Bhd., Penang

3. Millennium Substrates Sdn Bhd.,Penang

4. QDOS Flexcircuits Sdn Bhd., Penang

5. ItraMAS, Penang

6. Pentamaster Sdn Bhd., Penang

INSTITUTION

1. University of Malaya

2. UTM

3. UiTM

4. UTAR

5. USIM

6. UniMAP

7. School of Engineering, USM

For any inquiries regarding the services offered, kindly contact Dr. Subramani Shanmugan [This email address is being protected from spambots. You need JavaScript enabled to view it.]

| |

Equipment Analysis

|

Description |

Rate (RM)* |

| 1 |

T3Ster® DynTIM™ Tester |

- To measure thermal resistance against bond line thickness and applied pressure

- To measure accurate thermal conductivity of TIM materials |

400 - 600 |

| 2 |

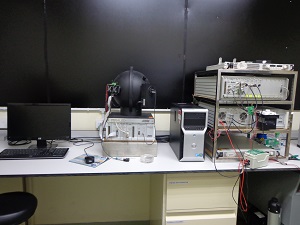

T3Ster - Thermal Transient Tester with pneumatic TIM test frame |

- To measure the thermal resistance and impedance of the electronic packages at various pressures and temperatures (for LED package) |

250 - 600 |

| 3 |

TeraLED radiometric characterization |

- To perform a combination of temperature and optical measurements to obtain LED (Light-emitting Diode) and SSL (Solid State Lighting) characteristics. |

200 - 400 |

| 4 |

Hot Disk® Instrument – TPS 2500 S (Thermal Conductivity Analyzer) |

- To measure the thermal conductivity of solid and liquid samples |

250 - 450 |

| 5 |

Thermal imaging IR camera (ThermoIMAGER 160, MICRO EPSILON) |

- To monitor or observe the thermal profile of the LED |

150 - 250 |

| 6 |

Taber Shear/Scratch Tester (Model 551) |

- To measure scratch resistance of thick films on various substrates |

100 - 200 |

| *Depends on the testing condition and customer |

| |

EQUIPMENT/ SOFTWARE |

DESCRIPTION |

| 1 |

3-zone Thermal CVD Furnace |

To synthesize or annealing thin film and bulk materials |

| 2 |

Vacuum Annealing Furnace |

To anneal thin film or bulk materials in various gas ambience |

| 3 |

Spin Coating Unit |

To prepare thin film on various substrates |

| 4 |

Electrochemical Deposition Unit |

To deposit metal or oxide thin films on conducting substrates |

| 5 |

Mass/Gas Controller |

To control or monitor flow of gas in reaction chamber of furnace/oven etc. |

| 6 |

UPRtek MK350 LED Meter |

To measure optical properties of LED |

| 7 |

JULABO Refrigerated/Heating Circulator |

To control ambient temperatur for T3ster during electronic device testing |

| 8 |

Paperless Recorder FX10101 (Data Logger) |

To measure / log temperature of multichip electronic device |

| 9 |

Vacuum Oven |

To heat/treat/anneal bulk and thin film materials at various gas ambience or vacuum |

| 10 |

Heating Oven |

To heat/treat/anneak bulk and thin film materials at various gas ambience |

| 11 |

T3ster Master Analyzer 1.4 |

To analyse cooling transient data from t3ster |

| 12 |

Hot Disk Thermal Constant Analyzer Software 6.0 |

To analyse transient data from thermal conductivity analyser |

| 13 |

TeraLED view 2.2 |

To analyse optical data of SSL from TeraLED |